Our ionizers effectively neutralize electrostatic charges, improving the quality of work in ESD zones.

Industrial Ionizers: Indispensable in Electronics, Plastics and LDPE Film Production

Industrial ionizers play a key role in many industries where electrostatic control is essential to ensure the quality and safety of production processes. In this article, we will focus on the use of ionizers in electronics, plastics and LDPE film production. We will discuss the advantages of using ionizers, their various applications and provide examples of how our ionizers are used in various industrial sectors.

What are Industrial Ionizers?

Industrial ionizers are devices designed to neutralize electrostatic charges on surfaces and in the air. They work by generating positive and negative ions that neutralize excess electrostatic charges. In industrial environments, where electrostatics can lead to serious problems, ionizers are a key solution.

Advantages of Using Industrial Ionizers

Efficiency of Production Processes: Ionizers help maintain the stability of production processes, which translates into increased efficiency and reduced downtime.

Reduction of Product Damage: Industrial ionizers effectively prevent damage to products caused by electrostatic discharge. This is especially important in electronics production, where even the smallest discharge can lead to component failure.

Improvement of Product Quality: Control of electrostatics using ionizers leads to improved product quality, reducing the number of defects and faulty components.

Increased Safety: Neutralization of electrostatic charges reduces the risk of fires and explosions in environments where flammable materials are present.

Ionizer Applications in Electronics Manufacturing

Electronics manufacturing is one of the most demanding environments when it comes to electrostatic control. Even a small amount of electrostatic discharge can damage delicate components, leading to component failure and increased production costs.

Testing and Quality Control: Ionizers are used in testing and quality control areas where precise measurements and testing are essential. Neutralization of electrostatic charges ensures accurate and repeatable results.

Assembly Lines: Ionizers are used on assembly lines where electronic components are particularly susceptible to electrostatic discharge. Ionizers can help maintain a safe working environment.

Clean Rooms: Clean rooms are often used in electronics manufacturing where electrostatic control is key. Ionizers help maintain low electrostatic levels, which is essential for producing high-quality components.

Advantages of Using Ionizers in Electronics Manufacturing

- Protection of Sensitive Components: Ionizers effectively protect sensitive components from damage.

- Reduction of Product Defects: By controlling electrostatics, the number of defective products is significantly reduced.

- Increased Productivity: Stable production conditions lead to increased productivity and reduced downtime.

Application of Ionizers in the Plastics Industry

- Injection Molding: Ionizers are used during the injection molding process to prevent problems with dirt attraction and improve the surface quality of the products.

- Extrusion: In the extrusion process, ionizers help control electrostatics, which is especially important in the production of plastic films and pipes.

- Packaging: Ionizers are used during the packaging of plastic products to prevent problems with electrostatics that can lead to damage to the packaging and products.

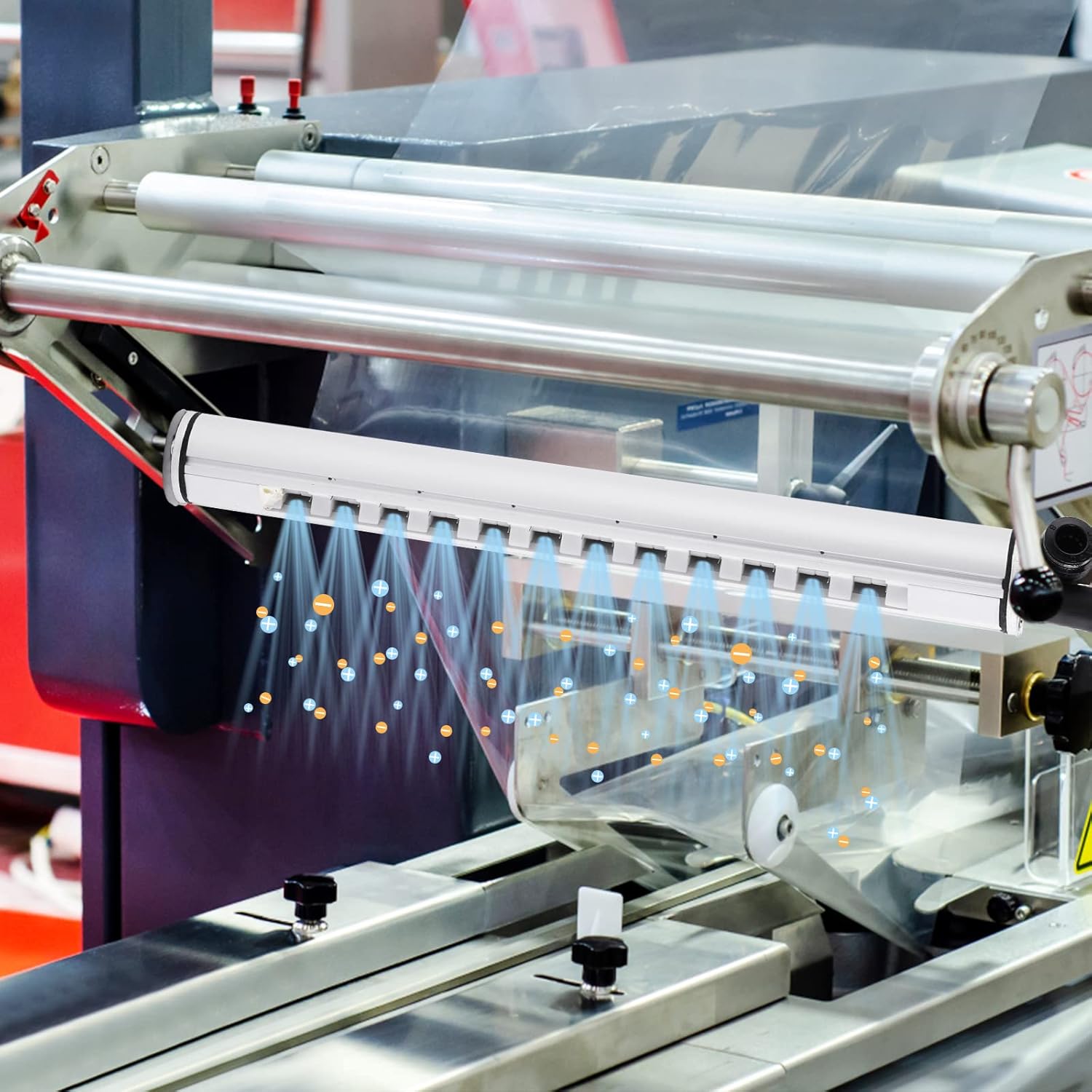

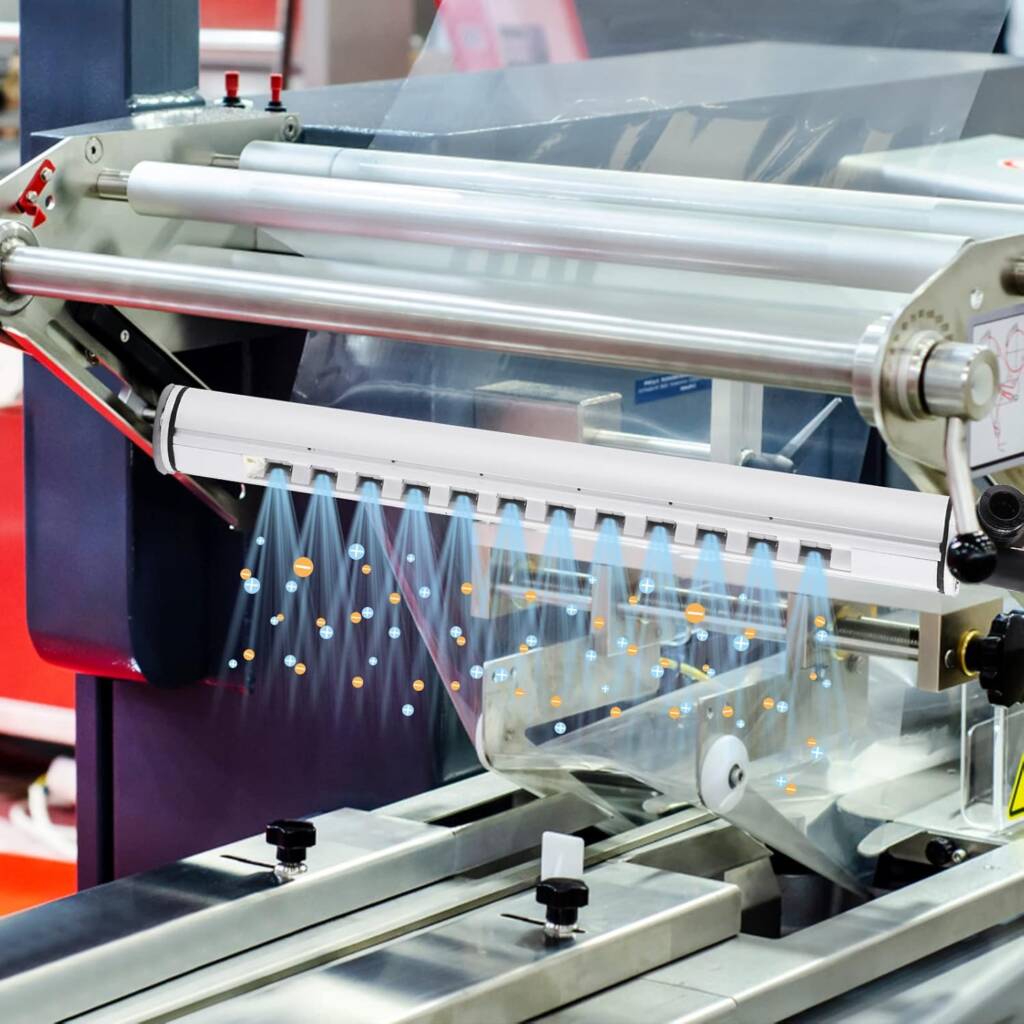

Application of Ionizers in LDPE Film Production

- Film Production Lines: Ionizers are used in LDPE film production lines to prevent electrostatic problems during the extrusion and winding process.

- Packaging and Storage: Ionizers are used during packaging and storage of LDPE films to prevent the attraction of contaminants and damage to packaging.

- Testing and Quality Control: Ionizers are used in quality control laboratories to provide accurate and repeatable measurements of LDPE film properties.

In packaging production, electrostatic control is crucial to ensure product quality and safety. Ionizers are used at various stages of packaging production to prevent electrostatic problems that can lead to damage to packaging and products.

In the printing industry, ionizers are used to control electrostatics during the printing process. Electrostatic charges can lead to print quality problems, the attraction of contaminants, and difficulties in handling paper and other printing materials.

In the pharmaceutical industry, ionizers are used to control electrostatics during the production and packaging of drugs. Neutralization of electrostatic charges is essential to ensure the purity and quality of pharmaceutical products.

In the textile industry, ionizers are used to control electrostatics during the production and processing of fabrics. Electrostatic charges can lead to fabric quality problems, attracting contaminants, and difficulties in the weaving and finishing processes.

How to Choose the Right Industrial Ionizer? Key Factors to Consider.

Choosing the right industrial ionizer depends on several key factors that must be considered to ensure effective electrostatic control.

- Type of Manufacturing Process: Ionizers vary depending on the type of manufacturing process. It is important to choose an ionizer that is suitable for the specific conditions and requirements of the process.

- Size of Area: The size of the area to be protected from electrostatics also affects the choice of ionizer. Ionizers can have different operating ranges, from small devices to large industrial systems.

- Type of Materials: Different materials may require different levels of electrostatic control. It is important to choose an ionizer that is suitable for the specific materials used in the manufacturing process.

- Safety Rules: Industrial ionizers should meet all applicable safety standards to ensure safe and effective operation in the manufacturing environment.

Why Choose Our Industrial Ionizers?

Our industrial ionizers offer the highest quality and reliability, making them an ideal solution for various industrial sectors. Here are some reasons to choose our products:

Technical Support: We offer comprehensive technical support to help our customers choose the right solutions and ensure their effective operation.

Innovative Technologies: Our ionizers use the latest technologies to provide effective and reliable electrostatic control.

High Efficiency: Our products offer high efficiency and durability, which translates into long-lasting and reliable operation.

Ease of Use: Our ionizers are easy to install and use, allowing for quick and effective implementation in a production environment.