Our BGA stations enable precise soldering and repair of advanced integrated circuits, increasing production efficiency.

BGA Stations: A Key Element of a Professional Electronics Workshop

BGA (Ball Grid Array) stations are an essential element of modern electronics workshops. They are used for precise soldering of BGA integrated circuits, which are increasingly used in advanced electronic devices such as smartphones, laptops, tablets and IoT (Internet of Things) devices. In this article, we will look at what BGA stations are, what they are used for, what benefits they bring, and discuss the importance of antistatic tables and chairs in the context of working with this type of device.

What are BGA stations?

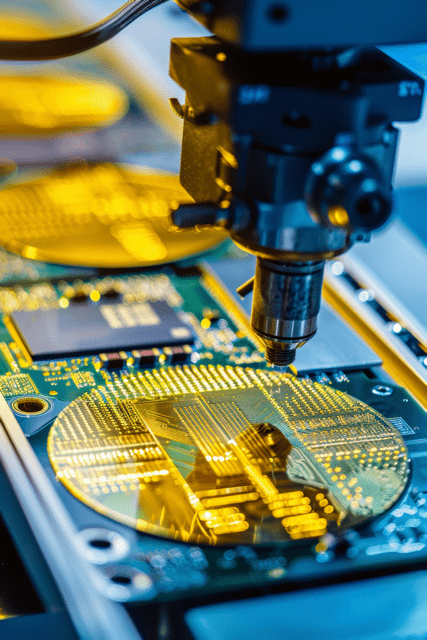

BGA stations are advanced soldering devices that allow for the assembly and disassembly of integrated circuits with Ball Grid Array connections. BGA is a technology for mounting integrated circuits in which components are soldered to a printed circuit board (PCB) using small solder balls placed on the bottom of the circuit. This technology allows for an increase in the number of connections compared to traditional methods, which is key to the miniaturization and increased efficiency of modern electronic devices.

BGA Station Applications

BGA stations are used in many areas, including:

Consumer electronics production: Assembly of BGA systems in smartphones, tablets, laptops, etc.

Repairs and service: Dismantling damaged BGA systems and replacing them with new ones.

Prototyping: Creating prototypes of new electronic devices using BGA systems.

Research and development: Testing and developing new technologies and electronic solutions.

Types of BGA stations

BGA stations can be divided into several types depending on their technological advancement and purpose:

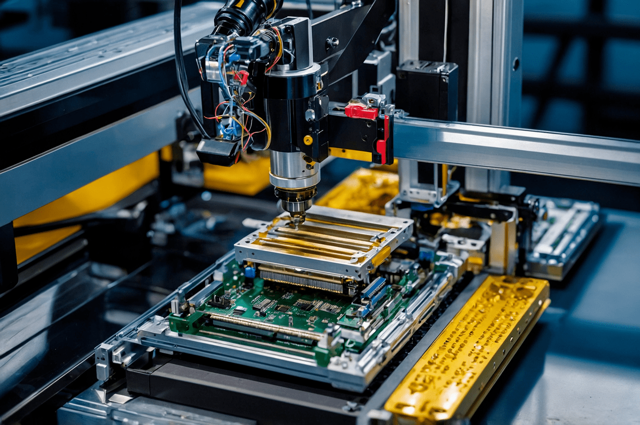

Industrial BGA stations: Designed for mass production of electronics. They are distinguished by high efficiency, process automation and the ability to work in continuous mode.

Basic BGA stations: Designed for simple assembly and service work. They are characterized by lower price and lower precision.

Professional BGA stations: Equipped with advanced functions, such as precise controlie temperaturą, systemy wizyjne do precyzyjnego pozycjonowania układów, a także automatyczne procesy lutowania.

How does a BGA station work?

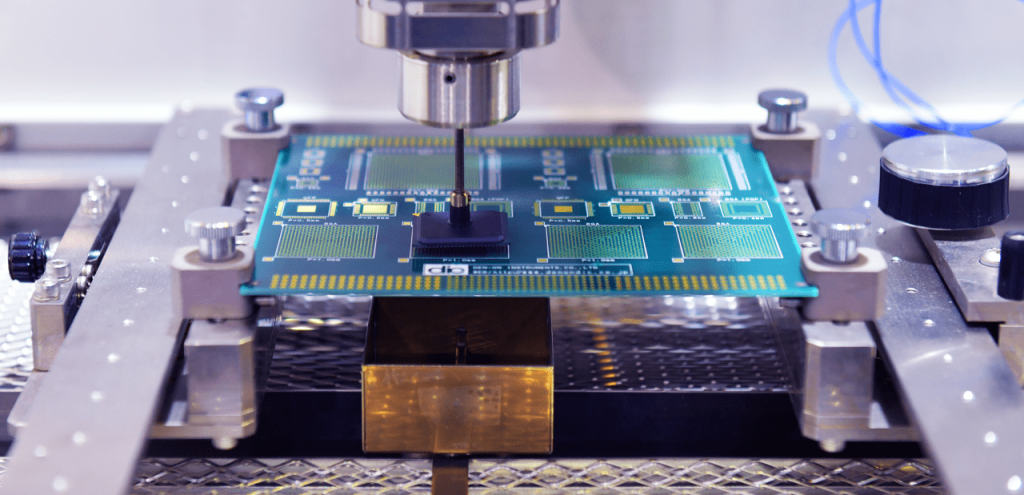

A BGA station consists of several key components that together enable precise soldering of integrated circuits:

Worktable: The place where the printed circuit board with the BGA circuit is placed. It is important that the table is antistatic, which prevents damage to the circuits by electrostatic discharge.

Soldering head: The device responsible for heating the BGA circuit and soldering it to the printed circuit board. In professional BGA stations, the head is equipped with precise temperature sensors and control systems.

Vision system: A camera or a set of cameras that allow precise positioning of the BGA circuits. This allows for precise placement of the circuit on the printed circuit board.

Control software: Computer programs that manage the soldering process, control the temperature, time and other process parameters.

BGA soldering process

The BGA soldering process consists of several stages:

Preparing the printed circuit board: Placing the printed circuit board on an antistatic worktable, protecting it from electrostatic discharge.

BGA preparation: Placing the BGA on the soldering head, calibrating the vision system.

Preheating: Heating the PCB and BGA to the appropriate temperature using the soldering head. This process is controlled by the control software.

Soldering: Soldering the BGA to the PCB by melting the solder balls placed on the bottom of the system.

Cooling: Cooling the PCB and BGA to room temperature.

Benefits of using a BGA station

Using a BGA station in an electronics workshop brings a number of benefits:

Versatility: The ability to work with different types of BGA systems, which is especially important in prototyping and service.

Precision: Advanced BGA stations enable precise soldering of integrated circuits, which is crucial in modern electronic devices.

Efficiency: Automation of the BGA soldering and disassembly processes increases work efficiency and reduces the time needed to complete tasks.

BGA stations are an essential part of modern electronics workshops, enabling precise soldering of integrated circuits using Ball Grid Array technology. Choosing the right equipment, including antistatic tables and chairs, is crucial to ensuring safety and efficiency of work. Advanced BGA stations and appropriate antistatic protection measures can achieve high quality and reliability of assembled electronic systems.